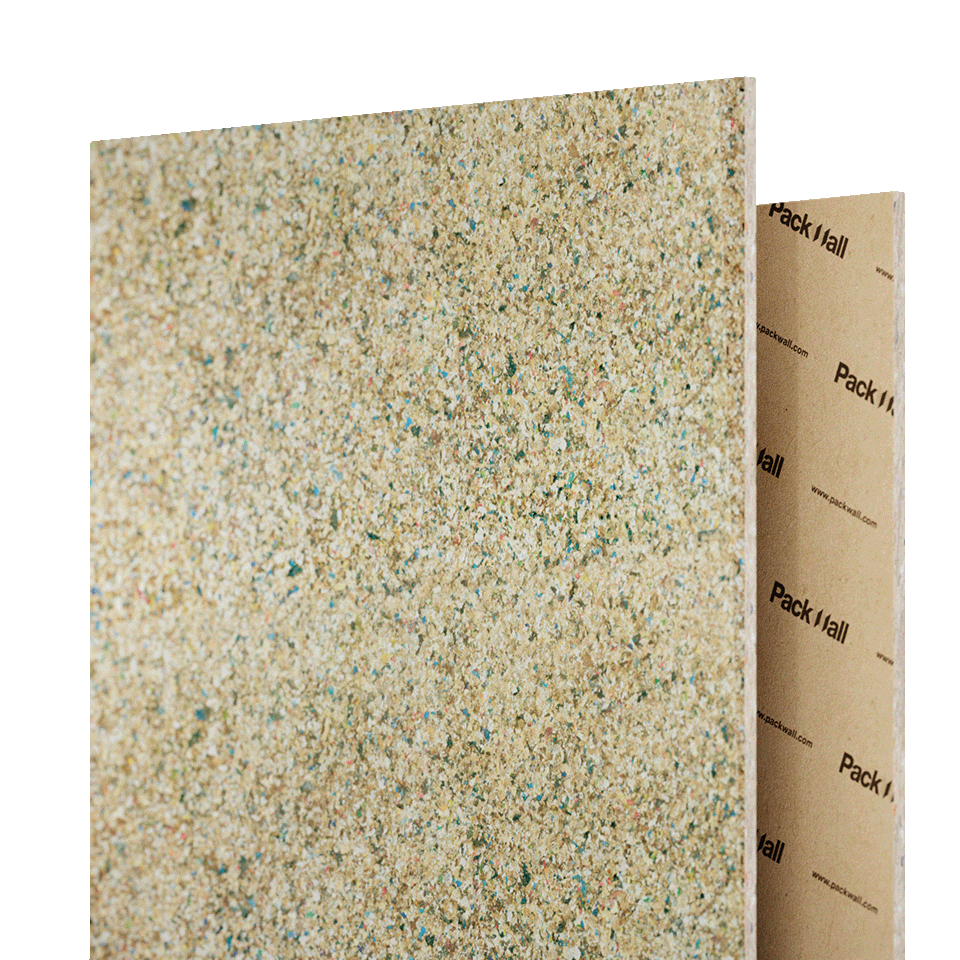

DESIGN board is created by coating the base composite with smooth transparent parchment paper. Thanks to this, the unique texture of the pressed covers stands out, which can be used as an original interior decoration in the form of atypical cladding panels.

DESIGN boards can be varnished, veneered or laminated. They retain all the qualities of the base board, such as strength, soundproofing, easy handling and, of course, health safety.

The construction panel can carry more than 65 kilograms per 4.5 mm bolt at a thickness of 12 mm, thus allowing direct assembly of furniture without the need to look for beams or use special fasteners.

85-90% lower CO2 emissions than alternatives. Low content of volatile organic compounds, no additives.

Our composite panels are pressed at high temperatures and pressures and their surface paper is similar to plasterboard. The result is a smooth panel that can be surface treated as required.

Made from 100% recycled material and the panels are 100% recyclable over and over again.

The same tools, fasteners and finishing methods are used for assembly, handling and subsequent modifications as for traditional wooden or plasterboard panels. No special knowledge or equipment is required.

The construction panel can be hot bent and curved for installation on rounded corners, arches or other non-standard shapes.

Excellent thermal and sound insulation compared to other construction panels. Sound is absorbed and heat is reflected back into the room.

PackWall composite panels can withstand large fluctuations in temperature and humidity, while maintaining their dimensions, shape and properties.

0,42 Kg CO2e / M2

100% waste

<= 0,19 W/(M*K)

~ 850 Kg / m3

100% recurring

>= 32 dB

D - s1, d1

≥ 0,061 N/Mm2

705 mí